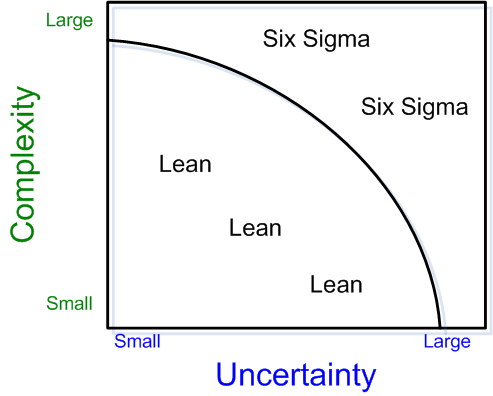

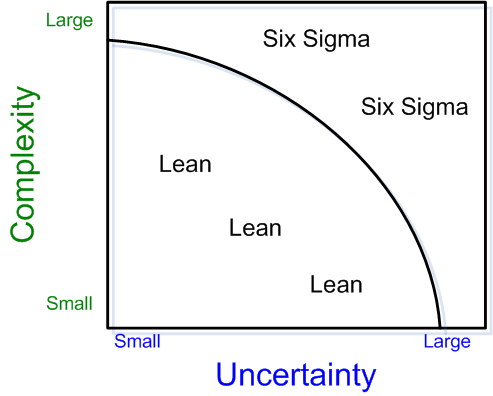

The diagram below gives an indication when to use a Six Sigma approach and when to use a Lean Manufaturing approach

The Six Sigma is preferred when the problem to improve the process is complex and the outcome of the improvement is uncertain. A Six Sigma project will result in bigger improvements and will point you fast into to major improvement directions, based on statistics that point out relations between cause and effect. Data about the process is required to use statistics.

Lean Manufacturing is based more on structured thinking and experience. The method is preferred of relatively simple process improvements and will take place step by step.

In many projects Lean Manufacturing tools and the Sis Sigma method are used together to get the best result, especially where the project has mid size complexity and uncertainty.